Comparing Different Growing Methods and Medias

Recirculating Systems

Recirculating systems are those that are closed-loop in nature and will either continually, or on a schedule, recirculate the same water and nutrient solution throughout the system. Although these types of systems can use less water, they also require much more involved cleaning steps both during and after production, which can lead to longer downtime and more labor and chemical intensive cleaning procedures. Additionally, these systems are much more dependent on pumps and valves and cannot be operated manually or a using low-tech approach. In general, all recirculating systems will have more issues with biofilm and pathogen residues, as well as an unbalanced loss of EC from plants taking up more of one nutrient than another.

Flood & Drain (Ebb & Flow)

Flood and drain systems are the most popular recirculating type systems. It involves growing plants in a passive substrate like rockwool, expanded clay, or coco coir. Nutrient solution is pumped up into a shallow bench or tray and the substrate is flooded, usually around 2 to 5 centimeters high. The substrate then will wick the solution to the rootzone where it can interact and be taken up by the plants. The solution is usually flooded for a few minutes until ideal saturation occurs, and then drained back out into a segregated reservoir.

The advantages of such a system is the simplicity of it. It is often employed in larger facilities with 2D rolling bench systems, where a permanent irrigation connection to each plant isn’t feasible. Although many such systems will have redundant pumps both for the flooding cycle and drainage cycle, this type of system can be sustained with only a single flood pump and allowing drainage through gravity alone.

The disadvantages of flood and drain systems include requiring larger nutrient solution volumes in order to flood the trays to the proper height, higher humidity during irrigation events, the entire nutrient solution being exposed to air and light during irrigation events, as well as problems with drains clogging with root or plant matter or other materials. Additionally, timer or operator failures could lead to flooding roots too long and causing damage. And like most recirculating systems, since the same solution is circulated to all plants, it greatly increases the likelihood of spreading rootborn or viral pathogens or pests among plants sharing a reservoir.

Aeroponic system with roots clogging drains

Aeroponics

There has been a recent renewed interest in aeroponic systems, with the rise of high pressure emitters and sensor technology. Aeroponic systems allow very precise control and monitoring of growing plants and their root zones with no external contribution of substrates holding water or nutrients. This creates a very linear relationship between the nutrient solution and what nutrients the plants are assimilating. From a research perspective, this makes aeroponic growing a great choice for manipulating inputs and seeing their effect while keeping other factors constant. However, aeroponic systems are anything but simplistic or easily scalable. Rootzone and solution temperature control becomes vital in such a system. Facilities will require having large backup power systems, as aeroponic plants completely depend on the emitters and have to substrate to hold water in the case of an extended power outage. Nutrients must only be fully soluble and inorganic, and root conditioner chemicals such as H2O2 or HOCL become continual necessities. The range of inputs is much more narrow. Additionally, aeroponic systems constantly mix air with water and will therefore grow much more biofilms and algaes compared to other systems, so it is generally recommended to change nutrient solutions frequently, which negates the water-saving benefits of a recirculating system.

DWC system consumed by plant roots

Deep Water Culture

Deep water culture systems offer many of the same benefits and shortfalls of aeroponic systems. However, they differ in that they can oftentimes be more low-tech, requiring only a single water pump keeping the system moving, and an air stone from an air pump oxygenating the solution. The volume of water per plant is generally larger than in an aeroponic system. But just the same, the nutrient solution temperature must be precisely monitored and controlled, extra cleaning steps and root conditioning inputs are generally required to reuse these systems, and backup power is a requirement. But there are no emitters to clog or fail.

Photo Credit: WGVU Public Media; Patrick Center

NFT

Nutrient Film Technique, or NFT systems, involve a thin film of flowing nutrient solution, usually on a bench or tray, with a floating support system (usually styrofoam or similar material) of free hanging plants. Generally, like deep water systems, the roots don’t have much actual substrate to grow into and hang freely from the floating support system. However, because the nutrient solution is in a very thin film, additional oxygen isn’t actively added into the root zone. Much like ebb & flow, the solution is exposed to a wide area, and oftentimes light and air can contact the nutrient solution, and potential contamination is spread around to all plants. Due to the shallow nature of these systems, plants with multiple life stages or robust root systems cannot be grown in these systems. They are designed for short lived plants, such as lettuce and herbs. The floating support systems are often inexpensive and can be disposed of, and the rest of the system is easier to sanitize than aeroponics or DWC.

Drain to waste, also known as feed-to-waste or flow-to-waste, includes various irrigation methods, such as drip irrigation, manual hand feeding, and other top-down irrigation styles. Drain-to-waste systems can often be precisely controlled to minimize actual runoff wastewater, using instrumentation and plant feedback. Since these systems have their irrigation branched off to each plant, there is no potential for cross contamination of root born disease or pest. Nutrients can be catered to each plant, zone, or growth stage, because the same nutrient solution isn’t being recycled. The downsides of such systems is that the drainage water does need to be accounted for and dealt with, either through municipal wastewater systems, evaporation, re-filtration, or water recycling services or techniques. Although it is often theoretically argued that recirculating systems are more water efficient than drain-to-waste systems, considering the known cons of recirculating systems and the reality of often having to dump entire spoiled reservoirs, this has not proven true in practice. There are a nearly endless array of substrates to choose from for drain-to-waste systems, depending on the availability, needs of the grower, and type of irrigation system in place. Even though it is referred to as drain-to-waste, the organically derived substrates such as coco coir, peat, or soil don’t necessarily need much drainage at all, if they are managed correctly through precise irrigation and buffering.

Examples of seedlings in expanded clay media

Expanded Clay

Clay pellets, often sold as hydroton or hydrocorn, are irregular or circular pellets created by heating and expanding clumps of volcanic clay. This is a very inert substrate, with a lot of room for oxygen, but it has a very low water holding capacity. This substrate is best used for nearly constant imprecise irrigation. There is very little worry of overwatering roots. Free flowing emitters can be used, as the substrate really only provides a support structure for the roots and not much else.

Soil

Although soil can mean many things, it is generally accepted in horticulture that it is an aggregate of various organic components and amendments that can have various soluble and insoluble nutrient contributions to the root zone. No two differing soils are alike and growers will need to dial in their pH, nutrient requirements, and container size for each type of soil they are using. Generally, soils with a higher nutrient content require less fertilizer but will also provide the grower with less precise control. So long as soils are properly buffered, growers can monitor soil EC and water as needed, with little to no runoff. But growers will require more analysis or end up guessing when certain nutrients are depleted in the soil and need to be replenished on time.

Pictured: Ruck's Citrus Nursery using peat, Frostproof, FL

Peat

Peat-based soilless substrates (sphagnum peat, Lithuanian peat, etc.) are a dark organic aggregate that resemble soil, but do not have a significant nutrient content. This has been the substrate of choice for large horticultural and nursery facilities in the past. These types of substrates share a lot of benefits and similarity with soil, however they can be freely fed with a complete nutrient solution, without worry of the contribution of the substrate itself, so there is no guessing involved. They hold water and nutrients well, and have a high cation exchange capacity and naturally occurring acid pH. Because of this, they require pH buffering, generally lime or calcium carbonate. Peat can also contain a lot of fine particles and have some hydrophobic properties when dried, so aeration media must be added, such as perlite or pumice. It should also be noted that peat is derived from aged peat bogs and is controversial in its harvesting, with a lot of debate on the sustainability and renewability of this natural resource.

Rooted clones in rockwool propagation media

Rockwool

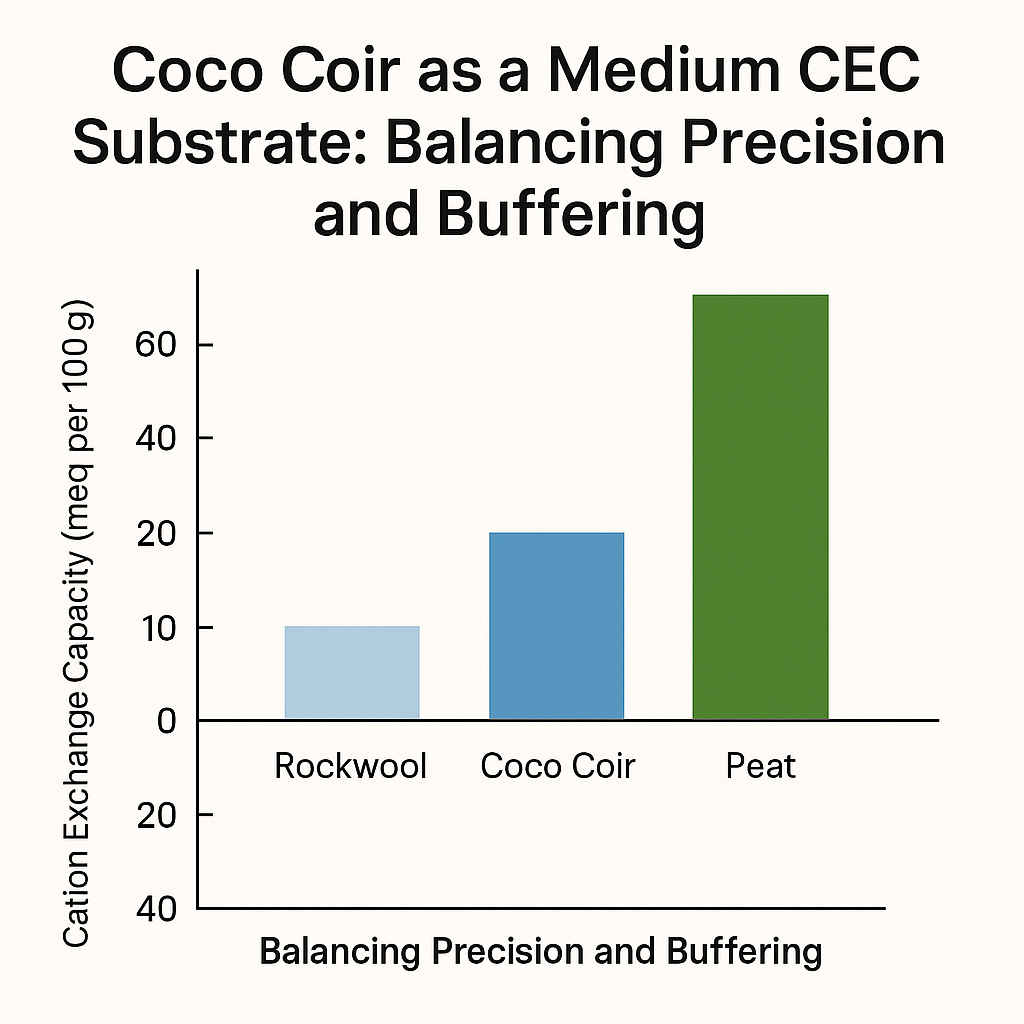

Rockwool or stonewool is an inorganic fiber-glass like solid matrix substrate manufactured by heating and spinning fine threads of wollastonite, a calcium silicate-based mineral. It naturally has a very low CEC and an alkaline pH. It requires pH conditioning with an acid solution to balance before use. It is a versatile substrate, with a medium water holding capacity, but low nutrient holding capacity. Rockwool is ideal for highly precise irrigation systems, but is less forgiving than other substrates with over or under watering and can often have issues with nutrient lock-out or salt build-up. Additionally, as it is a solid matrix and not a loose aggregate, it cannot be compressed for transport, is more delicate, and can have more issues with algae and other growth on light exposed surfaces.

Coco Coir

Coco coir is an organic substrate made from coconut husks. It is naturally pH neutral and doesn’t require pH buffering, and has a moderate CEC. Coco coir does naturally release some potassium and is therefore not completely inert, but this is easily balanced with feeding a higher calcium content fertilizer. A good quality coco coir will not have issues with sodium or other contaminants, however there are some brands on the market that may have these issues and growers need to work with trusted brands. Coco is an ideal substrate for drain-to-waste application in commercial facilities, as well as a great beginner, intermediate, and expert level growers that want both the precision and versatility of hydroponics paired with the easy and forgiveness of soil.

While every growing method and substrate has its unique strengths, coco coir stands out as the ideal choice for commercial growers seeking a balance of precision, sustainability, and ease of use. Unlike rigid substrates like rockwool or unpredictable soils, coco coir offers the perfect blend of hydroponic control with the forgiveness of organic media. Its neutral pH, moderate cation exchange capacity, and minimal buffering requirements make it highly versatile for both beginners and experienced growers. Additionally, coco coir supports sustainable practices by being a renewable byproduct of the coconut industry, unlike peat or rockwool, which raise environmental concerns. Whether used in drain-to-waste or hybrid systems, coco coir provides growers with the flexibility to optimize plant health while minimizing the risks of nutrient lockout and root diseases. For those aiming to achieve high yields with minimal hassle, coco coir is a proven, reliable, and scalable solution.